Know when it’s time to HIY

Exterior painting projects

How do you plan to prepare the surface for painting?

Will you prime before caulking and painting?

What areas are you planning to caulk?

What kind of paint do you plan to use?

Roofing projects

When it’s time to reroof, it pays to make sure the materials and workmanship are first rate. A poorly installed roof can cost you a fortune if it leaks or blows off in a storm. When you get bids from contractors, be sure they’re licensed, bonded and insured and can provide references from past customers. CDSSR – Roofers in Huntington Station Long Island NY provide roofing services to restore your roof to new and better protect your attic and ceiling.

Photo: romakoma/Shutterstock

Do you plan to tear off the old shingles and pull the nails?

How will you charge for extra work, like replacing rotted wood?

Regardless of how careful the contractor is to include all the necessary work in the bid, there are bound to be surprises. For example, it’s hard to know the condition of the roof sheathing until the shingles are removed, and at that point in the job you don’t have much bargaining power. That’s why it’s important to include in the contract an hourly rate for extra work, or a square-foot price for replacing the sheathing. If possible, plan to stay home on the day the roofers tear off the shingles so you can work with the contractor to establish an agreeable price for repairs.

Photo: L Barnwell/Shutterstock

Will you replace damaged or rusted flashing?

Will you replace the roof vents and valley flashing?

Asphalt driveway projects

Fly-by-night contractors are common in the asphalt industry, but there are ways to avoid them: First, don’t buy from door-knockers —reputable contractors seldom resort to this technique to get jobs. Then ask your contractor the following questions to get a long-lasting driveway and the most bang from your buck.

Photo: Matthijs Wetterauw/Shutterstock

How are you planning to prepare the base for the asphalt?

What equipment will you use to compact the driveway?

How thick will the asphalt be once it’s compacted?

In most areas of the country, a 2- to 3-in. layer of asphalt is sufficient if it’s installed over a stable base.

Will you slope the driveway to avoid standing water?

Water pooling on or at the edges of an asphalt driveway can cause damage and shorten the life of the asphalt. Make sure your contractor plans to slope the driveway and surrounding area for good drainage.

How do you plan to finish the edges of the asphalt?

A top-notch asphalt job includes beveling the edges at a 45-degree angle and packing the asphalt with a hand tamper for durability.

Concrete driveway projects

A concrete driveway is a big investment that will last a long time if it’s done right. But choose your contractor carefully. Poorly installed concrete can crack, buckle and heave, leaving you wishing you’d spent a little extra up front for a first-class job.

Will you provide a sketch showing the dimensions of the driveway?

To make sure you know what you’re getting and to prevent any misunderstandings, ask for a sketch of the proposed driveway showing all the dimensions and how it intersects with existing structures like the garage, house or street.

Photo: Imagenet/Shutterstock

How do you plan to prepare the base for the concrete?

The type of soil under your driveway determines how much preparation is needed before the concrete is poured. It’s important to find a contractor who’s familiar with the local soil conditions and can recommend a course of action. Typically the best base for a concrete driveway is a 4- to 6-in. layer of compacted gravel.

How thick will the finished concrete slab be?

While 4-in.-thick slabs are the norm, adding an inch of concrete is a great investment. The extra inch adds only 25 percent to the amount of concrete needed but increases the strength by about 50 percent.

What are the specifications of the concrete you intend to use?

In its most basic form, concrete is a mixture of cement, aggregates (sand and gravel) and water. The proportion of these ingredients helps determine the strength of the concrete. Engineers we spoke to recommend a 4,000-lb. mix (strength) for driveways. Adding fiber mesh to the concrete mix increases resistance to hairline cracks and is a good investment. In cold climates, order air-entrained concrete to help the concrete survive freeze/thaw cycles.

Photo: Alison Hancock/Shutterstock

Do you plan to add rebar to reinforce the concrete?

How many control joints will you cut into the concrete?

Concrete driveways are going to crack. Control joints provide a weakened line that encourages the cracks to form where you won’t see them. For a 5-in.-thick slab, control joints should be added in a pattern of squares no larger than about 10 ft. The joints should be at least 1-1/4 in. deep to be effective. Some contractors use a tool to cut the joints while the concrete is wet. Others return to cut the joints with a saw after the concrete sets.Will you apply curing compound after you finish the driveway?

Concrete needs to cure for about a week to approach full strength. During this time, evaporation of the water in the concrete has to be slowed to allow proper curing. Misting the slab or covering it with wet burlap or plastic sheeting are two methods of slowing evaporation. But applying a liquid, membrane forming curing compound to just-finished concrete is better because it doesn’t require constant vigilance to succeed.

Gutters and downspouts

‘Seamless aluminum’ gutters are the most common contractor installed gutters. The quality of these installations can vary widely, so hire a contractor who’s been in business for several years and can show you examples of past work. Then ask these questions from guttering Manchester to be certain you’re getting the best-quality job.

Photo: Suti Stock Photo/Shutterstock

How will you slope the gutters so they drain?

It may look nicer to have level gutters, but it’s better if they slope slightly downhill toward the downspouts. Just a little slope, about 1/16 in. per foot, is all that’s needed. Long gutter runs may require downspouts on each end and a gutter that slopes both directions from the center.

How thick is the metal on the gutters you’re planning to install?

There are two common thicknesses of aluminum used for gutters, .027 and .032 in. If you’re getting bids on aluminum gutters, make sure the contractor is planning to install the thicker, .032-gauge gutters. If you are not aware of the installation process and the materials required for it you can contact professionals such as Proven Contracting & Roofing.

What size downspouts are you going to install?

Ask for oversized, 3 x 4-in. downspouts. They don’t cost much more but have the advantages of carrying more water and clogging less.

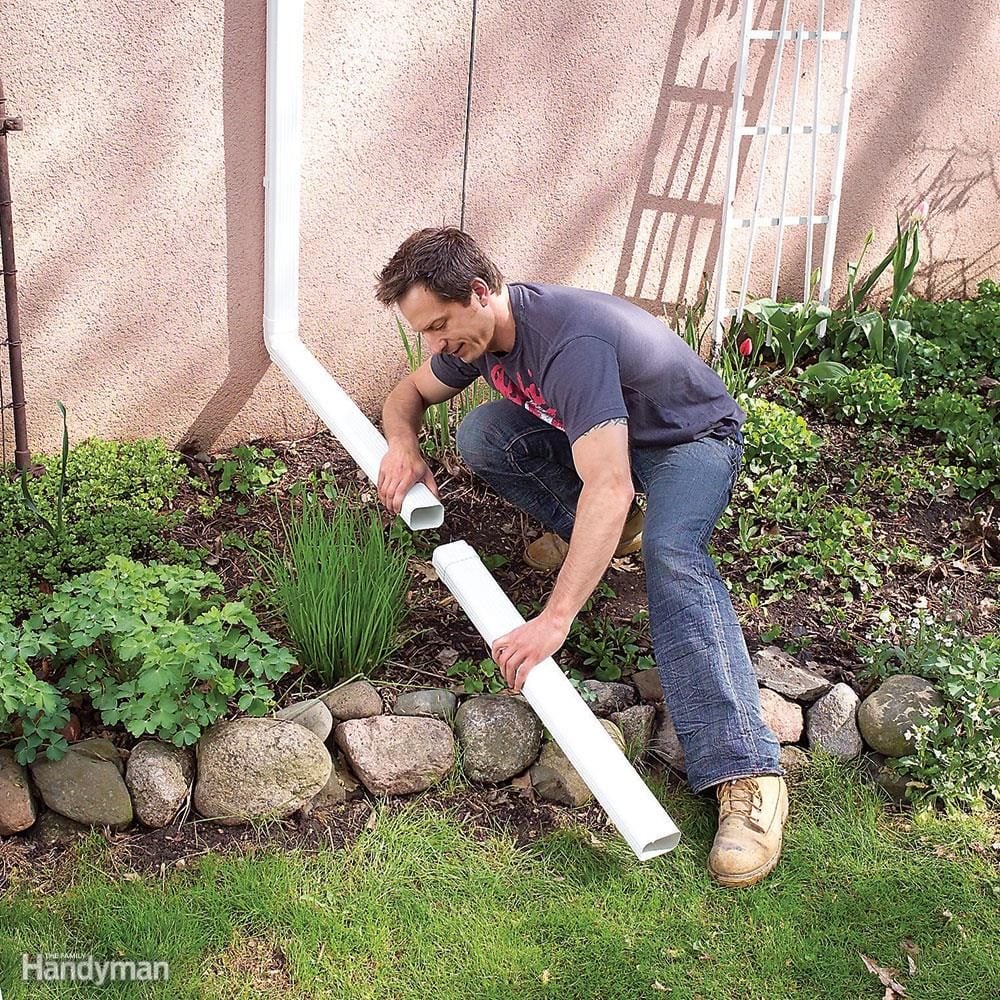

Does your bid include downspout extensions?

One of the main purposes of gutters is to keep water from accumulating near the foundation. Adding horizontal extensions to the bottom of the downspouts helps move the water farther from the house. Usually the extensions are just another length of downspout material attached to an elbow at the house. But flip up or roll-out versions are available for areas where downspout extensions might interfere with mowing or other activities.

How close together will the gutter hangers be spaced?

The guttering specialists will attach the gutters to your house with screws through the back of the gutter, and then add gutter hangers to support the front edge. Since aluminum gutters will bend if they’re not well supported, it’s important to have plenty of hangers to reinforce the outside edge. Be sure your contractor is planning to install a hanger at least every 3 ft. In climates where snow and ice remain on the roof over the winter, ask for 2-ft. spacing.

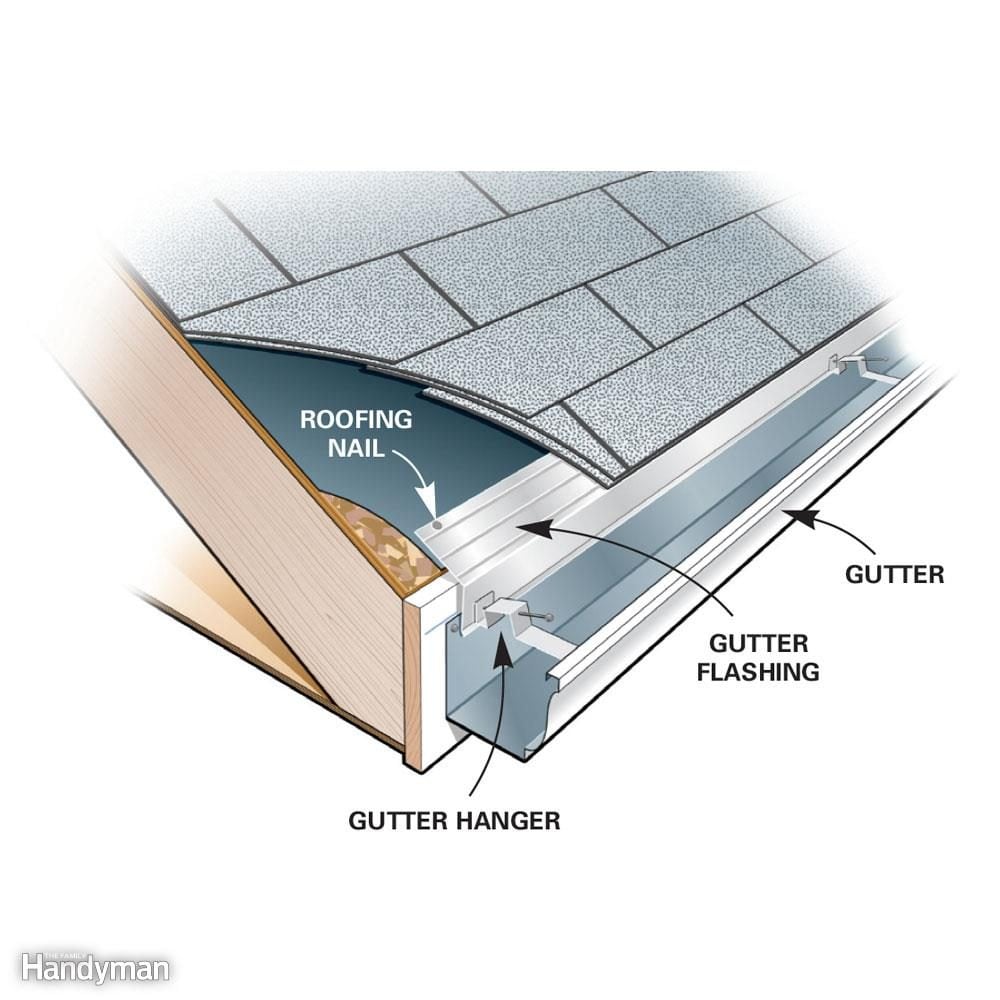

Are you going to install new gutter apron?

Water running behind the gutters can stain or otherwise damage the fascia board and soffit. To avoid this problem, the gutter installer should install metal flashing, also called gutter apron. Gutter apron slips under the shingles and over the edge of the gutter to direct the water into the gutter.

Ceramic tile floor projects

Properly installed tile floors should last decades. But poorly installed floors will start to crack or fall apart in a matter of years, if not months. Here are some questions to ask your tile contractor to ensure a long-lasting job.

Photo: Anna Maloverjan/Shutterstock

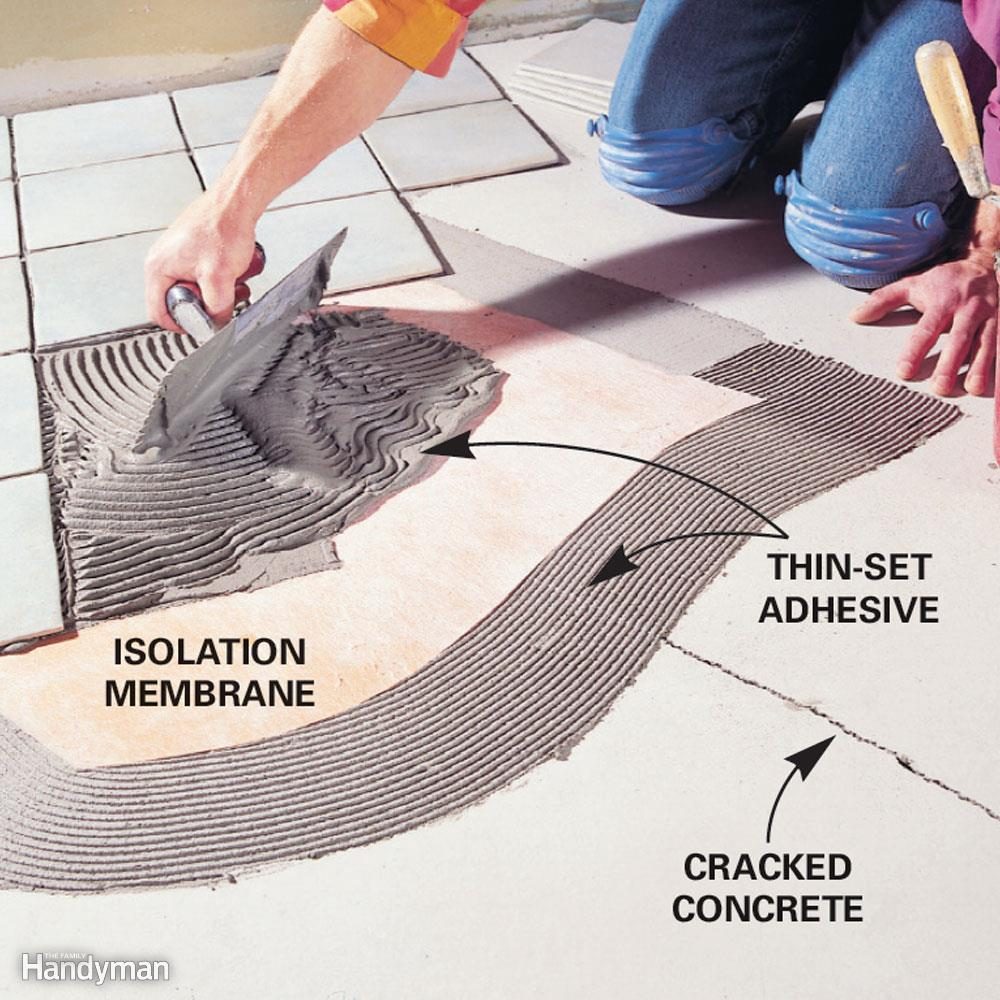

What material do you plan to install as a base for the tile?

Will you use latex mastic or thin-set adhesive to install the tile?

Do you plan to apply a grout sealer to protect the grout?

Grout sealers help keep grout clean and seal out water. Applying grout sealer is an easy job that you can do yourself. But when you’re comparing bids, it’s good to know whether it’s included.

How are you planning to deal with transitions to other flooring?

A well-planned and attractive transition is the mark of a top-quality tile job. Adding an adequate base often raises the floor level and creates a height difference at transition areas. In many situations, marble or solid surface (one brand is Corian) thresholds make attractive transitions to other floors. Ask tile contractors how much height difference there will be between transition areas and how they plan to deal with it.

Do you understand our house rules?

Be sure to specify things like where workers are allowed to eat and take breaks while working on your project. If you don’t want anyone to smoke, make that clear. Also talk about your expectations regarding language (no swearing around your kids?) and the type and volume of music that is okay with you.

If you have pets, determine where they will be during the project and what your expecations are regarding the workers. You don’t want your pets or workers stressed out.

Photo: wavebreakmedia/Shutterstock