Play it smart and stay safe when wiring outlets and switches

Buying a Dimmer Switch

Dimmer switches are available in many styles and configurations, including slides, knobs and touch-sensitive dimming mechanisms. However, check these key things:

- Capacity (how many lights it can control). The capacity will be measured in watts. Add up the wattage of the bulbs in all the fixtures the switch controls to make sure it falls within the switch rating listed on the package or instructions.

- Single-pole or three-way. Buy a ‘single-pole’ switch if one switch controls the lights or a ‘three-way’ if you have two switches controlling the same lights.

- Light type. Standard and halogen bulbs require standard incandescent dimmers. A few fluorescent lights can be dimmed with special dimmer switches, but most can’t. Low-voltage lights may also require special dimmers.

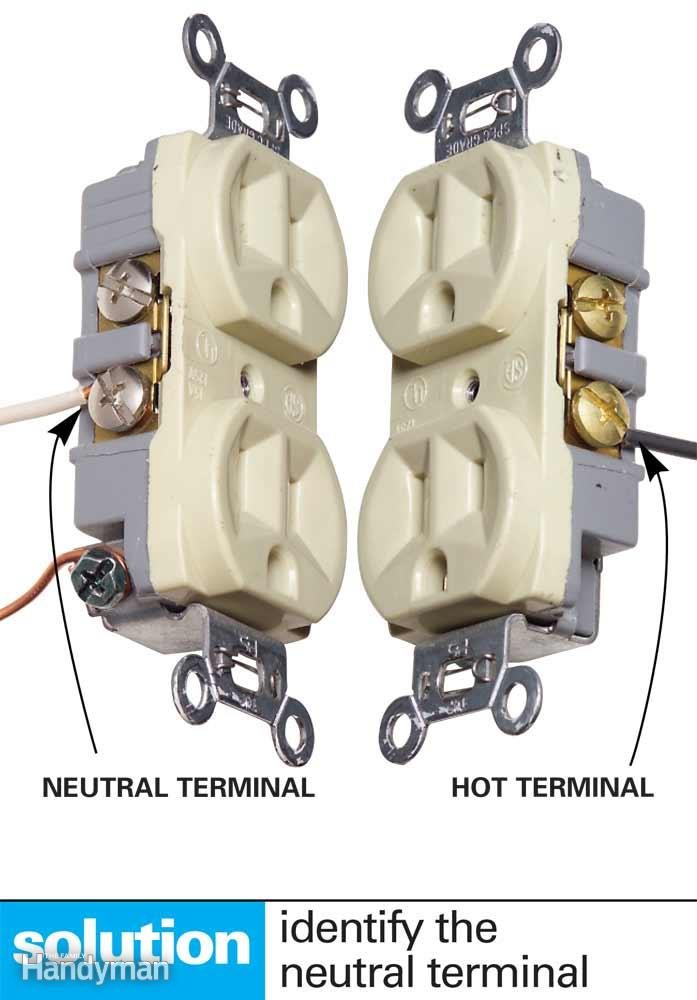

Don’t Reverse Hot and Neutral Wires

Connecting the black hot wire to the neutral terminal of an outlet creates the potential for a lethal shock. The trouble is that you may not realize the mistake until someone gets shocked, because lights and most other plug-in devices will still work; they just won’t work safely.

Always connect the white wire to the neutral terminal of outlets and light fixtures. The neutral terminal is always marked. It’s usually identified by a silver or light-colored screw. Connect the hot wire to the other terminal. If there’s a green or bare copper wire, that’s the ground. Connect the ground to the green grounding screw or to a ground wire or grounded box.

Cutting Wires Too Short

Wires that are cut too short make wire connections difficult and—since you’re more likely to make poor connections—dangerous. Leave the wires long enough to protrude at least 3 in. from the box.

If you run into short wires, there’s an easy fix. Simply add 6-in. extensions onto the existing wires. The photo shows a type of wire connector that’s easier to install in tight spots. You’ll find these in hardware stores and home centers.

Be Positive the Power’s Off

When you’re doing electrical work, don’t assume that because you flicked a switch or flipped a circuit breaker the power is off—always double-check. Buy a noncontact voltage tester and check all the wires in the box before you do any work—or plan on some melted dental work!

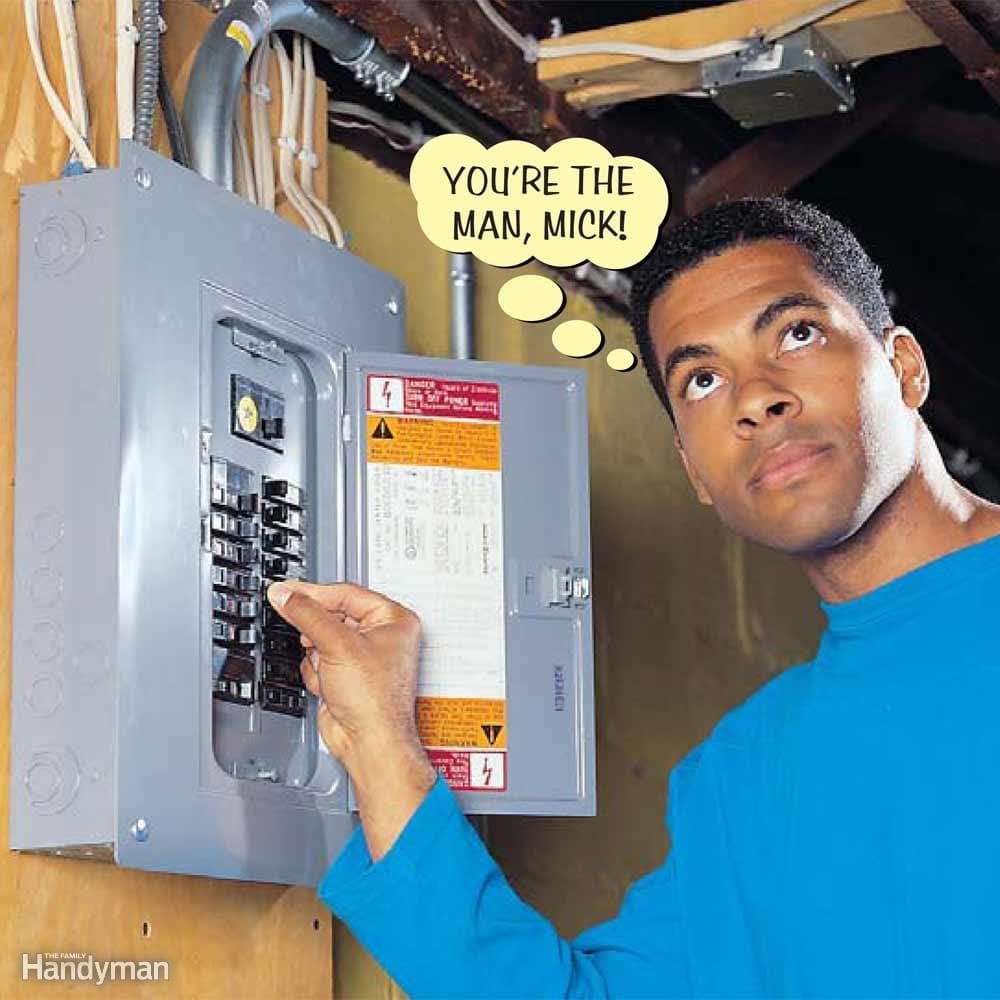

Circuit-Finding Radio

Instead of running upstairs, let the Rolling Stones help you find the right breaker. Find circuit breakers by plugging a loud radio into the outlet you’re working on. You’ll know you have the right circuit breaker when the music dies. But don’t assume the electricity is off in all the other outlets or lights in the room. Before doing any wiring, plug the radio into other outlets you plan to work on. Some duplex outlets can have different circuits running to adjacent outlets. To be safe, test both the top and bottom with the radio. For lights, turn the light switch on and off to be sure.

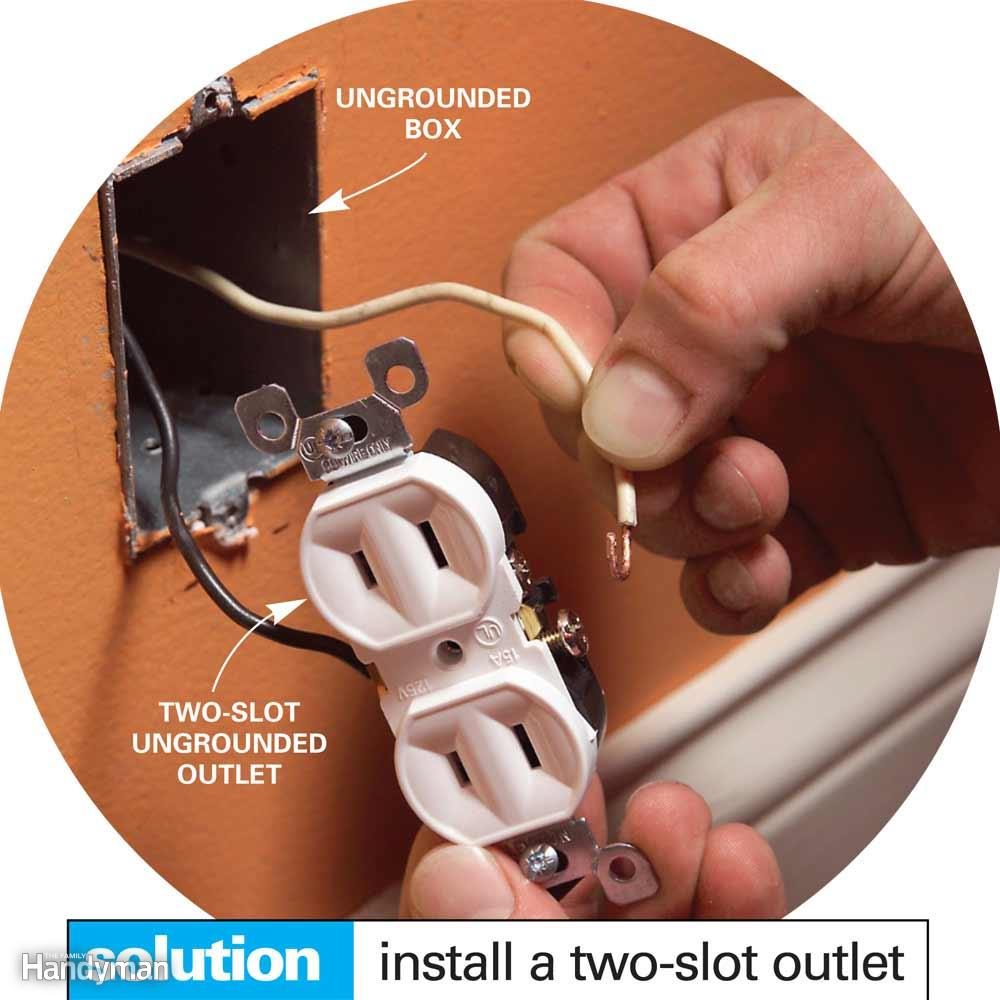

Don’t Install a Three-Slot Receptacle Without a Ground

If you have two-slot outlets, it’s tempting to replace them with three-slot outlets so you can plug in three-prong plugs. But don’t do this unless you’re sure there’s a ground available. Use a tester to see if your outlet is grounded. A series of lights indicates whether the outlet is wired correctly or what fault exists. These inexpensive testers are readily available at home centers and hardware stores.

If you discover a three-slot outlet in an ungrounded box, the easiest fix is to simply replace it with a two-slot outlet as shown.

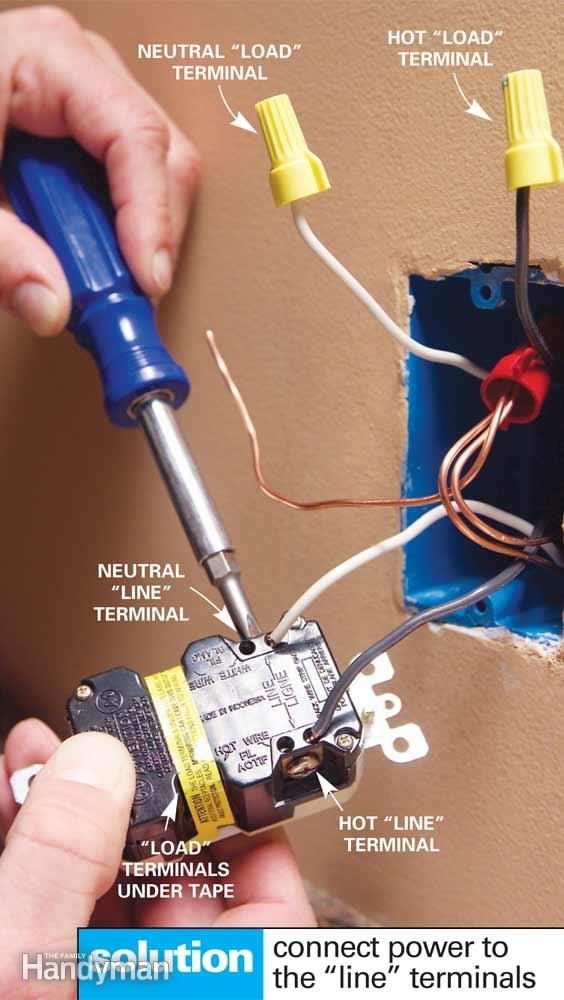

Don’t Wire a GFCI Backward

GFCI (ground fault circuit interrupter) outlets protect you from a lethal shock by shutting off the power when they sense slight differences in current. They have two pairs of terminals. One pair, labeled ‘line,’ is for incoming power for the GFCI outlet itself. The other set is labeled ‘load’ and provides protection for downstream outlets. You’ll lose the shock protection if you mix up the line and load connections.

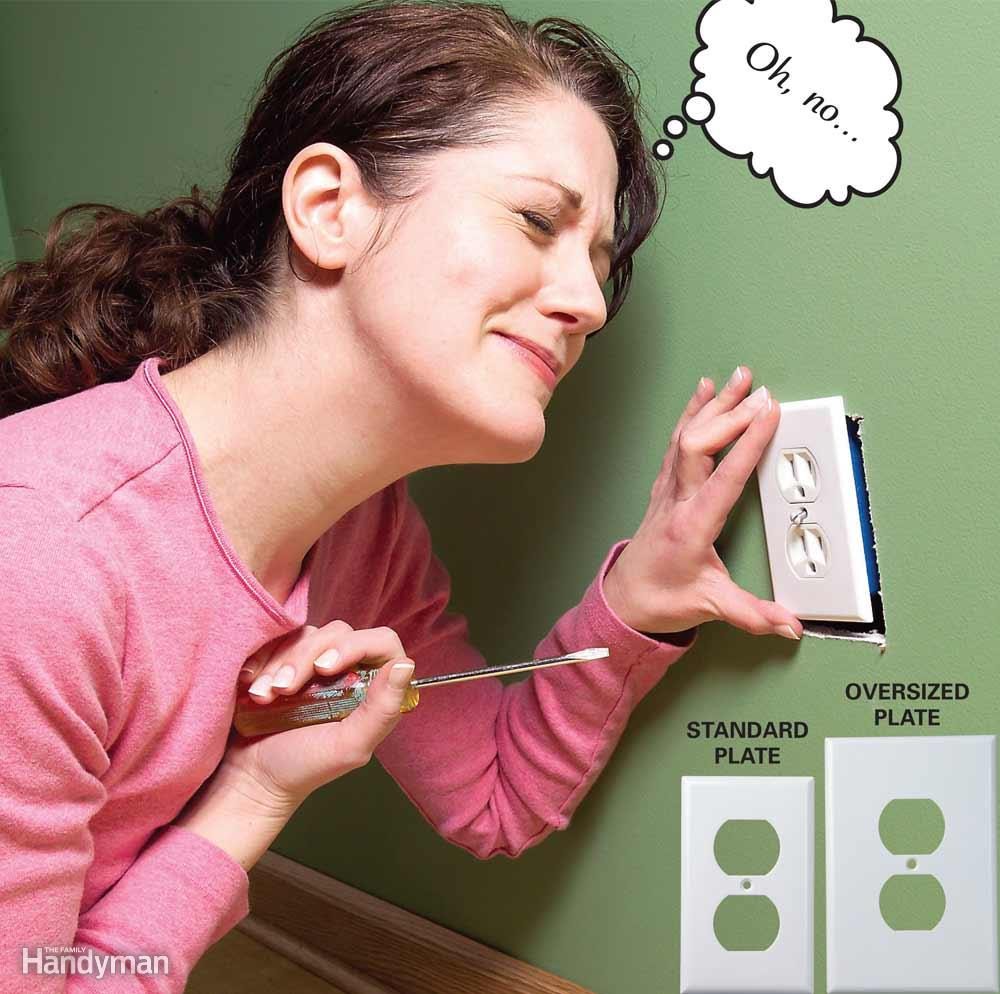

Oversize Plates Hide Mistakes

When you’re installing drywall or paneling, small mistakes can leave big gaps around electrical boxes. Luckily, there’s a product made just for this situation. ‘Oversize’ cover plates (about $1) for switches and outlets are available in standard colors at home centers and hardware stores. They’re 1/2 in. to 3/4 in. longer and wider than standard plates, so they can be a bit conspicuous. Electrical codes don’t allow gaps wider than 1/8 in. around boxes, so fill gaps with joint compound or caulk before you screw on the cover plate.

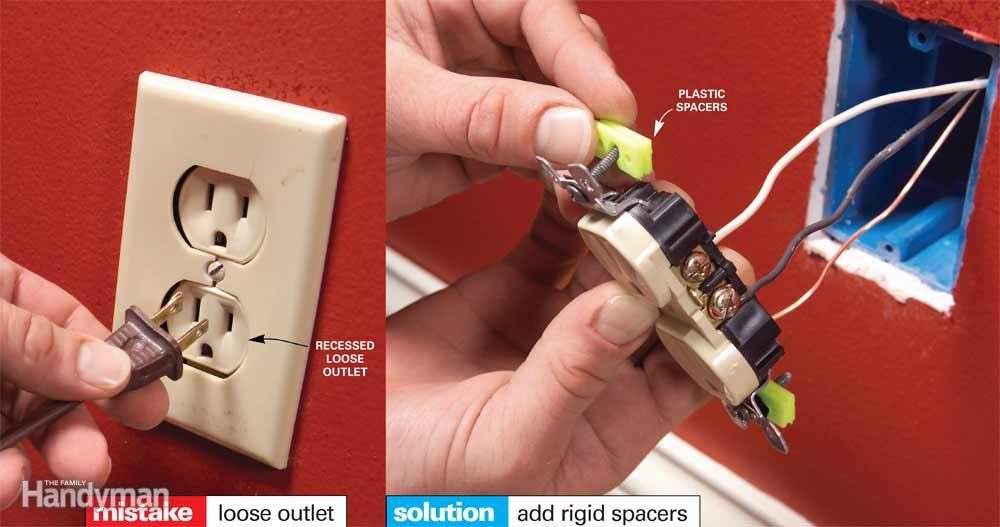

Poor Support for Outlets and Switches

Loose switches or outlets can look bad, but worse yet, they’re dangerous. Loosely connected outlets can move around, causing the wires to loosen from the terminals. Loose wires can arc and overheat, creating a potential fire hazard.

Fix loose outlets by shimming under the screws to create a tight connection to the box. You can buy special spacers at home centers and hardware stores. Other options include small washers or a coil of wire wrapped around the screw.

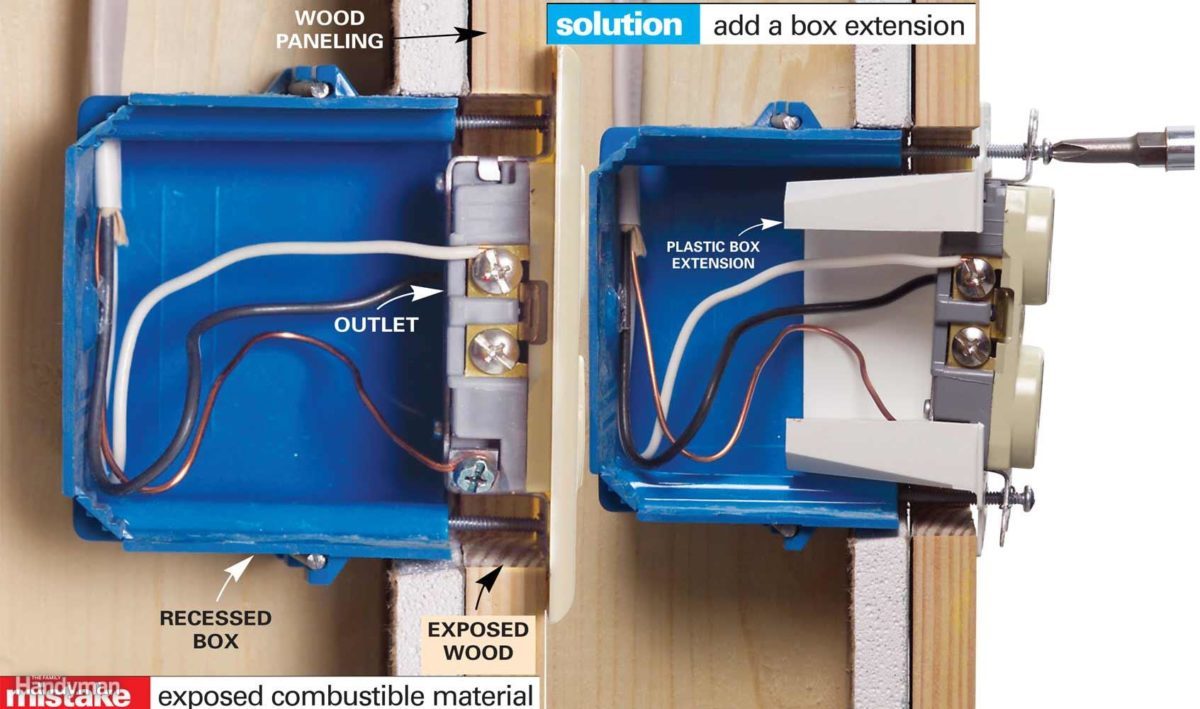

Recessing Boxes Behind the Wall Surface

Electrical boxes must be flush to the wall surface if the wall surface is a combustible material. Boxes recessed behind combustible materials like wood present a fire hazard because the wood is left exposed to potential heat and sparks.

The fix is simply to install a metal or plastic box extension. If you use a metal box extension on a plastic box, connect the metal extension to the ground wire in the box using a grounding clip and a short piece of wire.

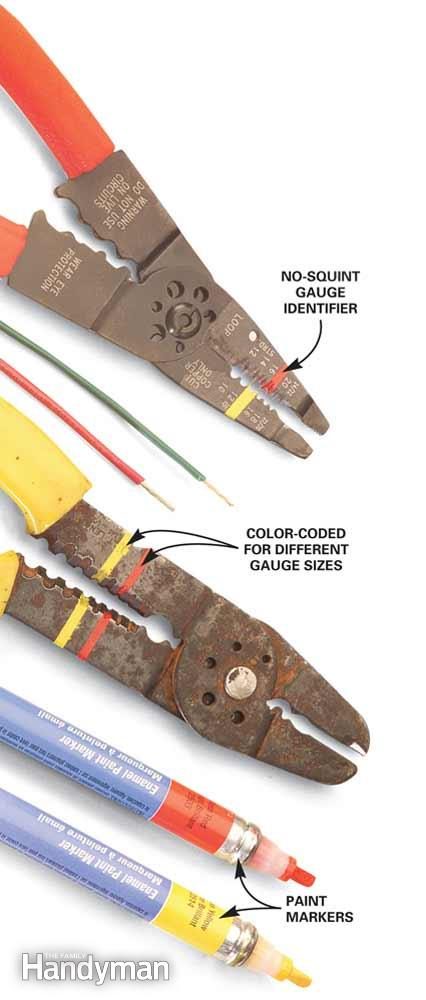

Squint-Free Wire Stripper

Ninety percent of the time, you use your wire stripper to strip the same gauge wire. Now, the days of searching your wire stripper for the right size hole are over. Use a Testor’s Enamel Paint Marker (about $3 at a home center) to mark a line across the hole. After a couple of minutes of drying time, you’ll be able to stick the wire in the marked hole with zero eyestrain and work a heck of a lot faster on your latest wiring project. If you’re stripping more than one wire gauge size, mark the holes in different colors.

Wrap Wires Clockwise Around Terminal Screws

Wrapping the wire clockwise ensures that the loop on the end of the wire will tend to close when the screw is tightened. If you put the loop over the screw in the counterclockwise direction, tightening the screw will force the loop open and could create a loose connection.

read more…

https://www.familyhandyman.com/electrical/wiring/wiring-switches-and-outlets/view-all/